Meteorological and Marine Radar Systems - Maintenance, Overhaul, Modernization, and Upgrade

The MTT-INFIZ company has extensive experience in working with civilian radar systems such as meteorological and marine radars. Over the years, our services have been used not only by leading national institutions in the field of meteorology such as Republic Hydrometeorological Service of Serbia but also by institutions in neghboring countries (Romania, North Macedonia, etc.).

The MTT-INFIZ company has extensive experience in working with civilian radar systems such as meteorological and marine radars. Over the years, our services have been used not only by leading national institutions in the field of meteorology such as Republic Hydrometeorological Service of Serbia but also by institutions in neghboring countries (Romania, North Macedonia, etc.).

Services that MTT-INFIZ can offer for meteorological and marine radar systems include, among others:

• General overhaul and maintenance of the radar;

• Repairs of assemblies and subsystems at the client's request;

• Provision of spare parts;

• Radar modification.

Modification of meteorological radar systems includes, among others:

Modification of meteorological radar systems includes, among others:

• Modification kit for digitalization of antenna position data;

• Modification kit for installing an LNA (low-noise amplifier) in the radar receiver;

• Modification kit for positioning the radar antenna by installing a system with PWM (pulse width modulation);

• Compressor-dehydrator modification kit for waveguide system's air;

• Replacement of the original magnetron on radars with Mitsubishi magnetrons HP10, HP20 i HP30.

The modification kit for digitalization of antenna position data consists of:

The modification kit for digitalization of antenna position data consists of:

• Encoder;

• Mechanical coupling assembly;

• Power source;

• Connection cable and connector;

• Sin/Cos converter.

The modification kit for installing an LNA in the radar receiver consists of:

The modification kit for installing an LNA in the radar receiver consists of:

• LNA;

• Power source;

• Coaxial-waveguide transition set.

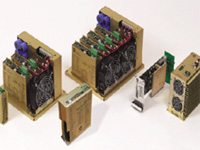

We especially emphasize that the company MTT-INFIZ has developed a family of LNAs for radar receivers in the frequency range from 1250 MHz to 9 GHz. All LNAs are realized in solid-state technology and have very low consumption.

Modification kit for positioning the radar antenna by installing a PWM:

By installing a modification kit for the antenna positioning system based on PWM, we replace the technologically outdated Amplidin. In this way, the following is achieved:

• Greater operational reliability;

• Simpler maintenance;

• Simpler system setup;

• Cost reduction;

• Improving the quality of regulation;

• Improving the accuracy of the entire system;

• Prolonging the operational lifetime of the power unit (engine and reducer).

Compressor-dehydrator modification kit for waveguide system's air:

• Depending on specific requirements, a modification kit is formed. The requirements relate to the required flow rate, outlet pressure, and required dew point.

• This kit enables the replacement of the entire system for generating air.